COMPONENTS DETAIL

Our methods, processes, and materials are unparalleled. Take an in-depth look at our innovative designs and processes and see how we deliver Gatti Performance!

OUR BLANKS

are the core of our performance. Making a blank that’s light, strong, and responsive is a challenge. Achieving this with feel and sensitivity is something else entirely. It requires ambitious engineering, advanced materials, and innovative processes.

We met this challenge over 40 years ago. Our goal was to create a single foundational platform that delivered five performance attributes without compromise, regardless of cost. As a result, our blanks embody:

1. Strength and Durability: Ensure consistent, non-degrading mechanical performance over the rod's lifetime.

2. Modifiable Mechanical Attributes: Ability to create different performance characteristics within a unified single design platform.

3. Scalability: The platform could be used across all line weights without compromising performance or durability.

4. Low-Mass: Minimize material usage to reduce mass and weight, enhancing micro-vibration transmission and sensitivity.

5. Thin-Wall: Eliminate variations in wall thickness and voids within the composite to create strength, torsional stability and eliminate recovery oscillation.

In addition, the platform must be materially upgradable as newer hybrid composites emerge through collaborations. These can be quickly integrated into new rod designs.

Our process is proprietary and not publicly shared. We can reveal some details.

COMPOSITES

Our hybrid-composite is cutting-edge. We combine Hy-Bor/Carbon Fiber filaments using a unique weave and fiber count, producing a high-modulus, high-strain-rate material that is not brittle. Developed in collaboration with Microtex/Kordsa SA in Italy, this hybrid composite fabric enables us to modify rod performance with unlimited flexibility while retaining robust, practical durability. The material was developed specifically for our unique vacuum/nitrogen high-pressure, high-temperature curing process. This advanced material is available to no one else—it is exclusively ours.

PERFORMANCE ACTIONS

Our advanced tapers create progressive, fluid-like axial loading and energy release over the entire rod, utilizing ALL available energy. Our unique multi-directional layups allow us to precisely tailor actions that are ultra-fast, moderate, or delicate without adding other materials, thereby avoiding added mass and weight. It is also the reason why Gatti rods do not feel stiff even in ultra-fast actions.

GEOMETRY & ACCURACY

Our exclusive epoxy cures at higher temperatures and under vacuum, then under high pressure to eliminate voids in the composite. This process ensures our blanks have a consistent and precise wall thickness with no spine. No spine means no “weak” side of the blank like other rods. The uniform thin-wall design eliminates adverse effects from unstable radial loading or twisting, providing unparalleled torsional stability without the added weight and mass of web-encasement materials. This process ensures consistent, repeatable casts, superior line control, and pinpoint accuracy.

SENSITIVITY & FEEL

Our Low-Mass Thin-Wall design transmits micro-vibrations significantly better, and in a broader frequency spectrum resulting in the superior feel and sensitivity Gatti rods are known for. This core design is used across all models and weights.

Science, advanced materials, and processes make our blanks mechanical works of art. Our processes create a lightweight, durable, accurate, and sensitive fly rod with purpose-tailored performance.

https://www.microtexcomposites.com/

GATTI PERFORMANCE SPACING (GPS)

ENERGY TO POWER

Physics gives a simple example of energy conversion to power: a fueled Ferrari racing engine is a tremendous source of potential energy. Unless this energy is converted into power, there is no movement and no legendary race car. Energy conversion creates the power.

When casting, a Gatti rod stores a tremendous amount of potential energy. This energy is also useless until it is converted into power, which creates movement. The time required to convert this energy is critical; the faster the conversion, the more power is produced in both examples.

ENGINEERED SPACING

Each guide on a Gatti fly rod creates a 90-degree energy load on the blank during casting or when playing fish. We engineer the number and position of the guides for every rod length and model to maximize energy conversion efficiency. The result: the conversion is FAST, VERY FAST. That’s what GPS does!

RESPONSIVE HANDLING

With GPS, ultra-fast energy conversion is engineered into the rod, mechanically converting energy to power faster. This makes Gatti rods responsive and quick. Mending and lifting the line effortless, and why our rods are legendary for ripping line off the water and throwing a forward cast in any direction without false casts. Faster energy conversion also delivers quick static recovery and virtually eliminates post-cast rod oscillation.

PERFORMANCE ADVANTAGE

Our design shoots line farther because the fly line is better contained and suspended, reducing friction and the adverse effects of wind and gravity. GPS exploits more load energy along the entire rod for increased power with all types of casts and greater lift ability when turning and playing bigger game fish. We mean GPS when we say, “Gatti rods look different because they are different”. When you cast and play fish, the enhanced GPS performance is a game-changing advantage.

OUR REEL SEAT

All new for 2026, designed from the ground up for unparalleled strength, function, and beauty.

SUPERIOR MATERIAL

We use structural-grade 6061-T6 aluminum large-diameter tubing for strength and symmetry. Moving components, end caps, hoods, and shoes are 6061-T6 billet-cut aluminum. Dual locking nuts are made from corrosion-resistant Grade 7 Titanium-Palladium alloy for unsurpassed durability.

PRECISION MACHINING

Reel seat components are precision CNC-machined from solid billet stock to ensure strength and consistency. Internal and external thread clearance is precisely cut to deliver washerless mechanical engagement. This design gives our reel seats a smooth, clean, lubricated feel and ensures solid security when installing the reel on the rod.

CERAKOTE PROTECTION

Cerakote is the clear choice for reel seat protection, bar none! It delivers the best:

1. Impact and abrasion resistance

2. Corrosion resistance

3. Non-Toxic, environmentally safe processes

Unlike anodizing, Cerakote is an advanced, ultra-durable thin-film ceramic coating engineered for harsh, high-wear environments such as military firearms and precision racing engine parts. Cerakote is 8 times more abrasion-resistant and 12 to 23 times more salt corrosion-resistant than any anodized product, including mil-spec III. Non-toxic, clean, sustainable, and both EPA- and RoHS-certified, Cerakote is the environmentally responsible choice at Gatti. See testing videos for proven results.

OUR WOOD INSERTS

showcase our commitment to craftsmanship and art. We source exotic burl wood worldwide and handcraft each insert to heirloom quality.

PROCESS

Entire root burls are skillfully cut into small blocks, highlighting grain complexity, shade, and color in their raw state. These pieces are stabilized, lathe-turned, hand-sanded, and finished to perfection.

We conduct a final evaluation to achieve the best visual aesthetics with the rod blank and wrap colors. Only 10% of the original blocks are chosen for a Gatti Fly Rod. Our wood delivers unsurpassed individual beauty for every rod we make!

OUR GRIPS

are ergonomically designed and built for performance, durability, and sustainability.

CUTTING EDGE MATERIAL

Our grips use proprietary agglomerated cork, a sustainable material made from high-grade Portuguese cork aggregates blended with organic polymers. This material has unsurpassed durability, is nearly weight-neutral, and unlike natural cork, provides consistent density, color, and feel.

ALWAYS THE BEST

Natural cork is harvested annually from trees on a 9-year growth cycle, so the “best” cork comes from the best of any given annual harvest. At Gatti, we avoid this inconsistency. Our cork is engineered to our exact specifications, so every grip is consistent in quality, finish, and performance.

DURABILITY

Gatti grips are precision-machined and hand-sanded from solid blocks. Unlike traditional glued cork ring grips, ours provide superior durability. Our grips contain no filler putty, will not degrade, and clean easily to look new, without risking damage.

CUSTOM FIT

High-density rubberized cork in our grip butts increases durability where needed. This design allows precise cutting of the inlet for our reel seat, securely centering it with the rod blank. The solid structure better transmits micro-vibrations, enhancing Gatti's feel and sensitivity.

Our fighting butts are not just unique; they are performance-designed. Engineered at an optimal angle, they provide a larger contact area on the torso, reducing dig-in when fighting large game fish. They also give our rods their unmistakable look.

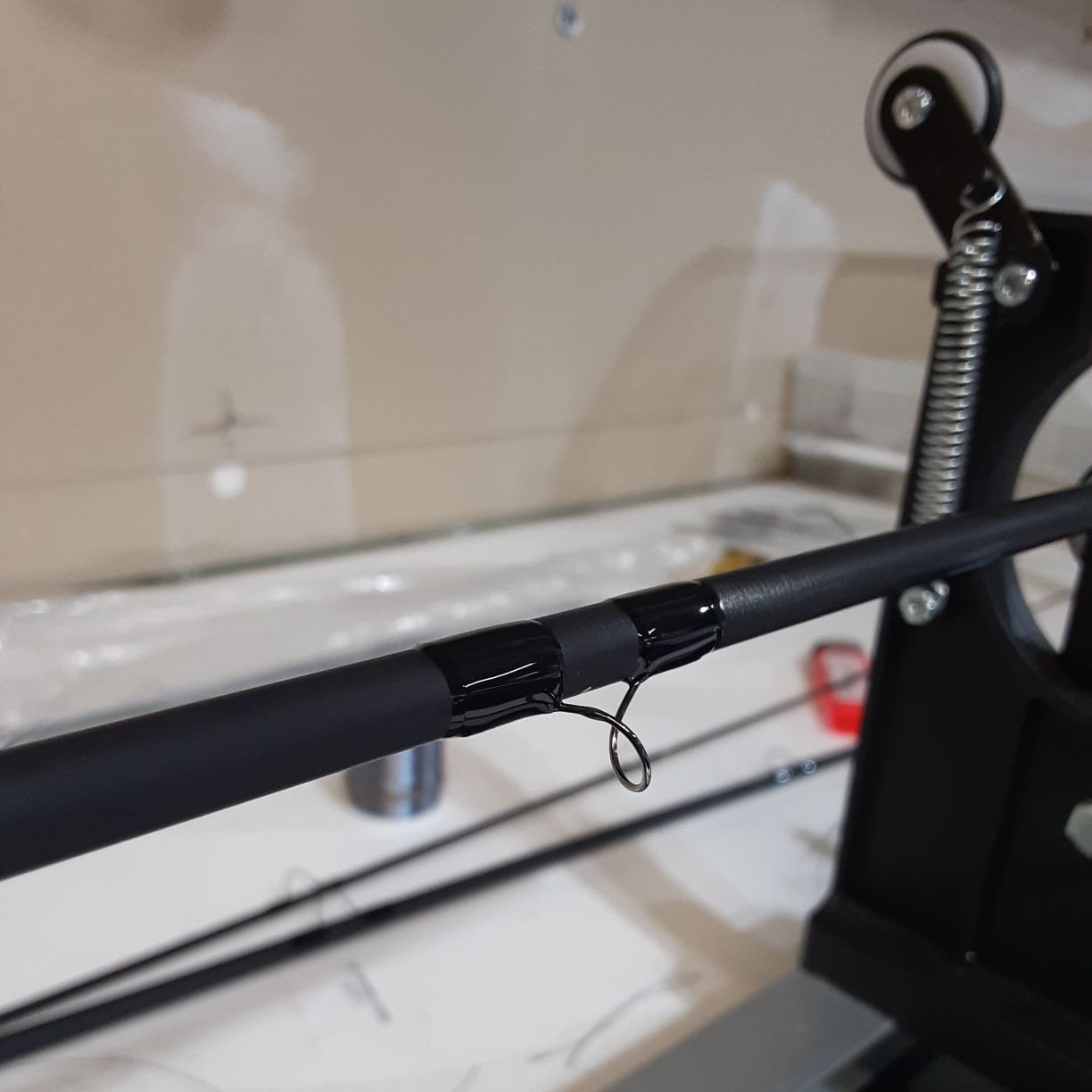

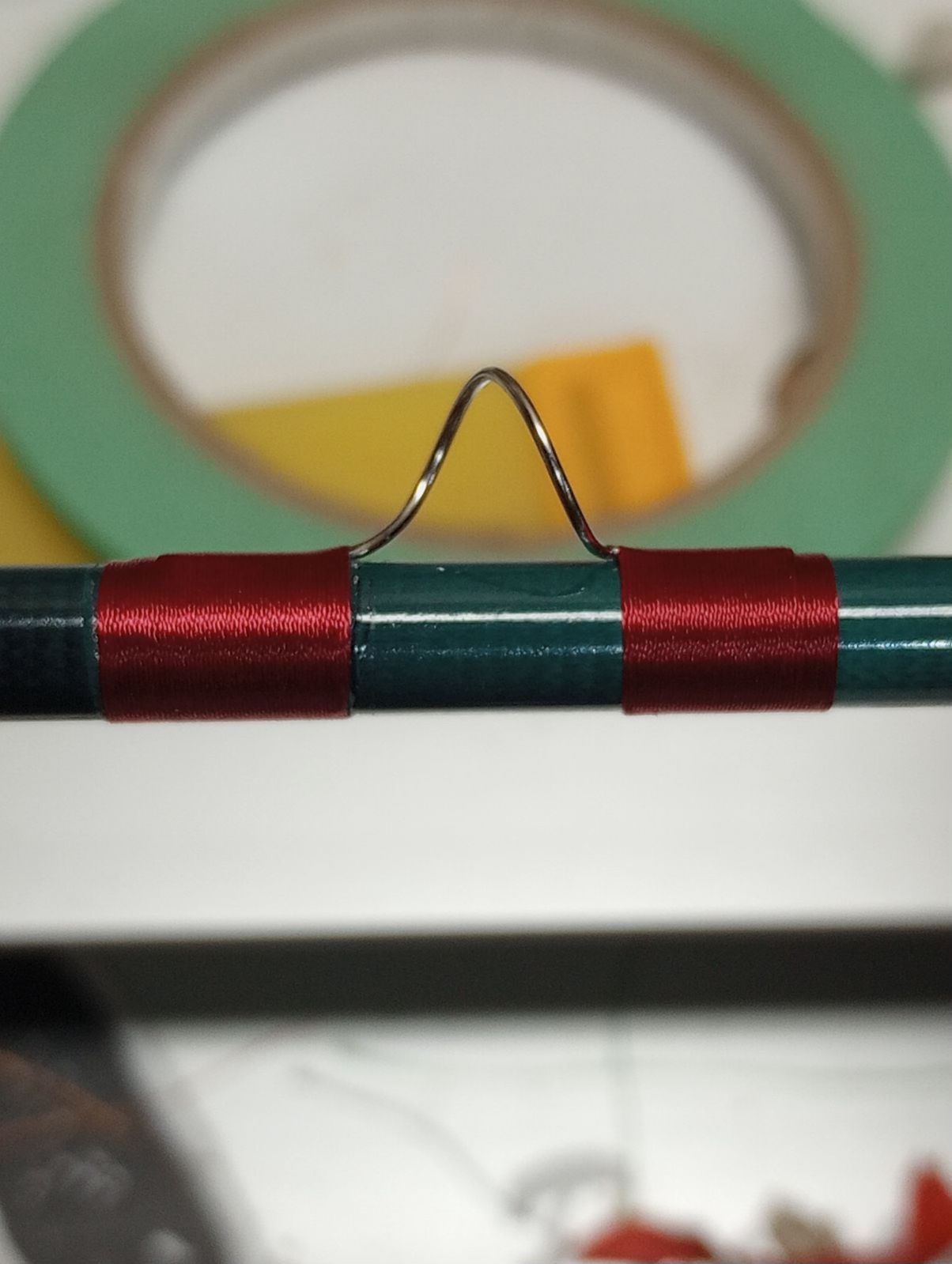

OUR RUNNING GUIDES

embody our commitment to advanced design, materials and unsurpassed performance.

ENGINEERED PERFECTION

Made by Mike McCoy of Snake Brand Guides, they are the most advanced running guides available. We worked with Mike on the patented ECOated single-foot and Universal guides. Both are crafted from 17-7PH stainless steel wire tempered to 64 Rockwell hardness. Their low-profile helical design reduces fly-line friction. The perfectly aligned feet, with a concave radius and taper, provide a superior gap-free fit to our blanks.

SUSTAINABLE

ECOating is a proprietary, sustainable plating certified by the Environmental Protection Agency (EPA) and Restriction of Hazardous Substances (RoHS). It is harder than nickel-chrome plating and avoids the hazardous waste generated by traditional nickel-chrome plating. These advanced guides deliver the performance, innovation, and environmental responsibility that Gatti demands.

OUR STRIPPING GUIDES

are the only components of a Gatti Fly Rod that are not manufactured in the U.S., because unfortunately, none are made there.

OVER 80 YEARS OF COMMITMENT

Rigorous testing led us to the only guide meeting our performance and environmental criteria: Fuji Tackle, a family-owned company in Shizuoka, Japan, founded in 1938.

PERFECTION IN DESIGN

The KW stripping frame design uses leading-edge technology, setting it apart from the competition. Made from a proprietary titanium alloy, it offers unmatched performance, strength, and corrosion resistance.

UNMATCHED DURABILITY

The KW frame is stamped, not welded, so no heat alters the metal or creates brittle spots. It is secure and rigid with no flexibility. The concave frame structure adds extra strength, making it the strongest titanium guide available. The patented forward canted design virtually eliminates line binding when shooting line.

INSERTS

The Torzite ring insert is a proprietary ceramic with a Mohs hardness rating of 9.4 for unsurpassed durability and frictionless performance. It is broader and flatter, with less mass, making it 40% lighter. The ring is deeply pressed and fully sealed with epoxy, protecting it from impacts and preventing separation from the frame, a problem with flexible guides. Fuji guides are produced under Ministry of Environment oversight, ensuring an environmentally safe process that we promote and require.

https://www.youtube.com/watch?v=0aZ2RfNxvrE

(Ring Impact Strength)

https://www.fujitackle.it/en/corporate.html

(Fuji Environmental Commitment)

https://www.youtube.com/watch?v=pCpbB4v6e3I

(Competitor Flexible Guides)

https://www.youtube.com/watch?v=sQ_e-Ci4cns

(Flexible Guide Repair Tutorial)

OUR HOOK KEEPER

Like all Gatti components, the hook keeper is designed and positioned for a specific purpose.

NEED

Anglers prefer to stow the entire leader outside the tip-top when moving to a new fishing spot. This prevents the monofilament leader from being crimped by the tip-top and needing straightening before the next cast. Many attach the fly to a running guide after looping the leader around the reel. This is not a good solution for many reasons.

DESIGNED SOLUTION

We place our hook keeper about 30 to 35 inches from the grip, on top of the rod and opposite the guides, for optimal convenience and functionality. It securely stores the hook with the sharp end facing away from the rod. This prevents the hook from scratching or scoring the rod blank, which could cause rod failure.

By placing the keeper one-third of the way up the rod from the butt, we ensure you have enough line out when wrapped around your reel. Your leader does not get bent or crimped. When not in use, it is positioned away from the grip and does not hinder performance.

FACTS

The three most common reasons a fly rod breaks while angling are:

1) Weak spot in the blank due to voids within the composite. (Gatti Rods do not have voids)

2) Striking the rod with the fly (e.g., bead head) while casting, creating microfracture leading to breakage. (It happens)

3) Hook scratching that scores the rod blank, creating a fracture point, much like when cutting glass with a glass cutter. (Avoided with our hook keeper)

OUR ROD TUBES

are made from a unique carbon fiber and fiberglass composite, making them a fraction of the weight of an aluminum tube and exceptionally durable. The end caps and threaded neck are machined from the same 6061-T6 aluminum as our reel seats, ensuring the same thread engagement and smooth feel.

OUR ROD SOCKS

They are handmade in Italy from 4oz sustainable cotton canvas sheeting, and dyed and screened with plant-based material.

Overview of Gatti Fly Rods process and production

position vs. competition.

1) Gatti designed, engineered, and tested every component of a Gatti fly rod. Everything is ours.

2) Our proprietary materials and processes are unsurpassed and available to no others.

3) We have complete quality control of every component we use to make our rods.

4) We have environmental oversight with our component manufacturers as they are in the United States.

5) We are EPA and RoHS-compliant in every aspect of our operations. Fostering our commitment to environmental stewardship.